THE BACKGROUND

West Virginia University at Parkersburg enrolls approximately 2,500 annual students in credit classes and additionally serves the community with non-credit classes, seminars,workforce development training, and workshops. WVU Parkersburg is the only public community and technical college in West Virginia accredited to offer baccalaureate degrees. The college’s primary service area consists of seven counties in West Virginia: Jackson, Pleasants, Ritchie, Roane,Tyler, Wirt, and Wood.

WVU Parkersburg was founded in 1961 as the Parkersburg Branch of West Virginia University. In 1971, it became Parkersburg Community College, one of the state’s first comprehensive community colleges. The institution was renamed West Virginia University at Parkersburg and rejoined WVU as a regional campus in 1989. State legislation in 2008 created a statewide network of independently accredited community and technical colleges, and, at this point, WVU Parkersburg became an independent institution while maintaining an affiliation with WVU.

West Virginia University at Parkersburg is now the region’s premier college recognized for quality education, commitment to student empowerment, workforce collaboration, and community involvement.

THEIR CHALLENGE

The Appalachian and Great Lakes Regions are the stage on which the energy transformation of this country is occurring. The engineers and industries located nearby play a vital role in reaching and exceeding energy independence as more resources are discovered nearer to our largest population centers than ever before. In-order-to keep up with this paradigm shift the curriculum offered to students must reflect the needs within the industry. WVU Parkersburg’s goal was to find a way to implement hands-on real-world experience to students where they are taught how to properly operate a process unit.

WVU Parkersburg works with multiple manufacturers in the Mid-Ohio Valley area through work-study to employment programs and requested the services of Valtronics to help create a process training unit that would fit the current educational needs.

OUR SOLUTION

The initial designs were developed by Valtronics Solutions to meet the criteria set forth by West Virginia University at Parkersburg. The final concept came from the collaboration between Pickering & Associates and the engineering team at Valtronics Solutions. Phase I was completed in spring 2017.

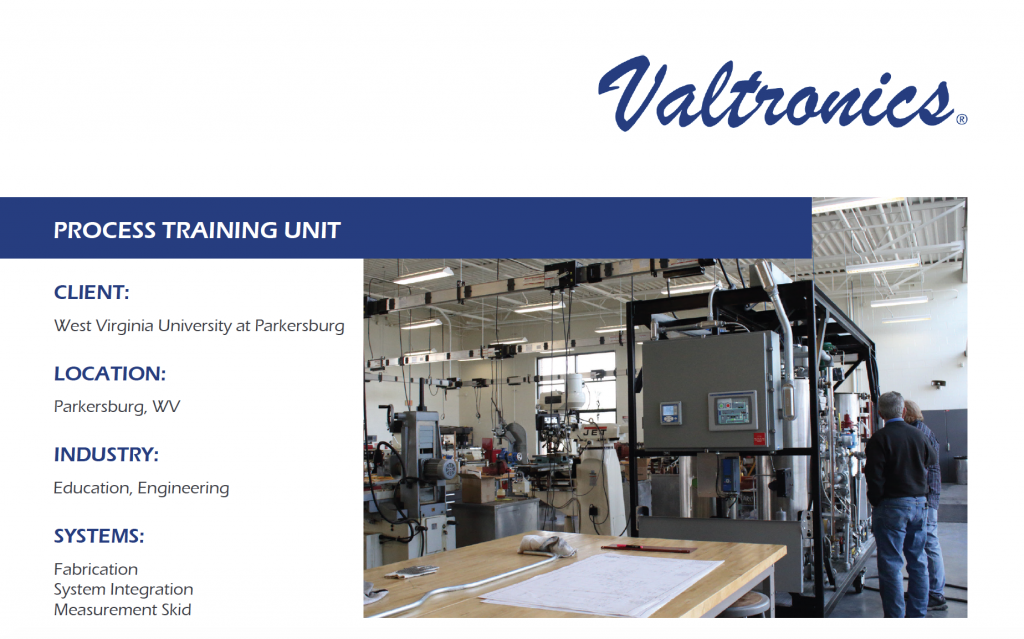

The process training unit is equipped with items from over 15 globally respected manufacturers. The complementary product lines enable a comprehensive process training unit design, representative of a measurement or control “skid,” commonly found within the energy industry. The skid includes pneumatic pressure & temperature control, a Coriolis mass flow meter, smart level & pressure transmitters, liquid process control valves, and dozens of other commonly found components and systems including pneumatic and electronic controls to further enhance the educational experience.

This unit allows chemical process control and electrical & instrumentation students to gain valuable experience with real-time measurement and control equipment to measure pressure, flow, level, and temperature utilizing programmable logic controller (PLC) hardware and software within a controlled educational environment. Through this processes students are also taught various scenarios that reflect real-world applications encountered after graduation and how to employ correct safety procedures when operating process equipment.